doctor blade

You can choose best blade for your printing conditions.

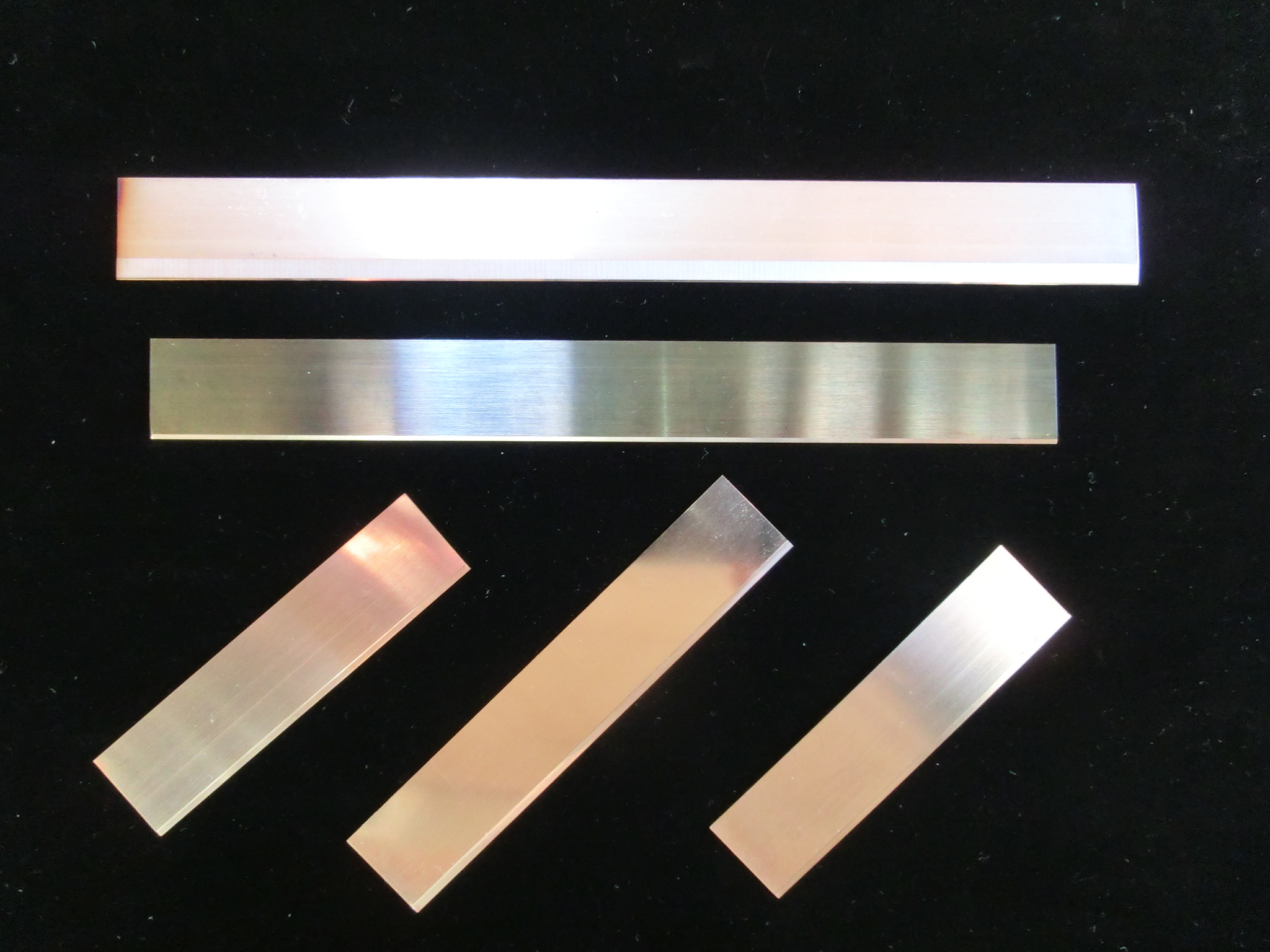

Tokushu Abe Seihanjo offers 4 types of doctor blades.

According to your printing conditions,

you can select most appropriate blade.

- We cut for your desired length

- One set of 10 pieces

- We supply long blade (310mm)

Type A: Parallel t0.3mm

It brings you long-term consistent printing because of its stability of blade edge angle.

Less scraping pressure than Type B but it’s suited for small plate, long term consistent printing, long product life, and for photopolymer plate.

Material: Steel (SK)

Thickness × Width(mm) t0.3×18.5

Blade shape: Parallel

Type B: Triangle t0.3mm

It’s more powerful scraping as compared to Type A.

Suitable for large plate and scraping adjustment is not needed.

Material: Steel (SK)

Thickness × Width(mm) t0.3×18.5

Blade shape: Triangle (Single edge 30°)

Type C: Triangle t0.5mm

It’s more powerful scraping as compared to t0.3mm blades.

Suitable for large plate and scraping adjustment is not needed.

Material: Steel (SK)

Thickness × Width(mm) t0.5×18.5

Blade shape: Triangle (Single edge 30°)

Type D: Triangle t0.9mm

It’s less bend with printing pressure and scrape evenly by less scraping pressure.

Suitable for solid printing, high viscosity inks, and large plates.

Material: SUS

Thickness × Width(mm) t0.9×20.5

Blade shape: Triangle (Double edge30°)

Bits of

knowledge

【1】Difference of blade shape

The difference of Triangle edge and Parallel edge is similar with pencil and mechanical pencil.

Pencil lead is sharp when it is sharpened but it will dull by use.

Mechanical pencil is not dull by use but we can’t write with high pressure.

For pad printing, Triangle shaped blade is commonly used.

The advantage of Triangle shaped blade is scraping with higher pressure, but scraping pressure is not stable because of abrasion.

Since Parallel shaped blade gives long term consistent printing because of stable scraping pressure.

For plate size 100 to 200mm, we recommend Type A because it has longer product life.

Also it is good for plate surface.

Bits of

knowledge

【2】All problems are solved by changing doctor blade???

We recommend Type D if you have problems of color unevenness of solid printing, too much scraping of etched area, pinholes or cobwebbing.

It is most powerful scraping among our product and expects to solve these problems.